The Twistlock

The “twistlock” or twist lock, is a metal piece used to join two containers during their transport by sea, road, or rail. The “twistlock” was developed in Spokane, Washington, in the 1950s by transport engineer Keith Tantlinger, who passed away on August 27, 2011, at the age of 92.

The “twistlock” or twist lock, is a metal piece used to join two containers during their transport by sea, road, or rail. The “twistlock” was developed in Spokane, Washington, in the 1950s by transport engineer Keith Tantlinger, who passed away on August 27, 2011, at the age of 92.

In his patent application, Tantlinger described his invention as a “coupler that has a housing with bosses at opposite ends that rotate a rotary element inside the housing.” To allow widespread adoption of his invention, Tantlinger eventually published his patent royalty-free, which led to the “Tantlinger twist-lock” being recognized as an international standard.

The twistlock is used by specialized container cranes. It fits into the corner of the container, a female piece with an oval hole 4.9 inches in diameter (12.45 cm). The twistlock itself is a male piece, either fixed on cranes and transporters (for example on ship decks) or removable to connect two containers together. The twistlock is about 10 cm long and 5.6 cm wide, with a pointed top to facilitate insertion. Once turned (twisted) 90°, it locks and cannot be removed unless turned another 90°.

There are semi-automatic twistlocks as well as FATs (Fully Automatic Twistlocks). The latter, considered partly responsible for the loss of containers at sea, have been abandoned. The FAT was designed to move into an open position when it detected a lifting effort by the crane or gantry. It turned out that the pitching motion of the ship in bad weather had the same effect and caused the twist-lock to open, then, when the ship rolled, the container would tip over. New models (C8A) seem to address this kind of problem.

References :

https://fr.wikipedia.org/wiki/Twist-lock

https://en.wikipedia.org/wiki/Twistlock

Photo credit :

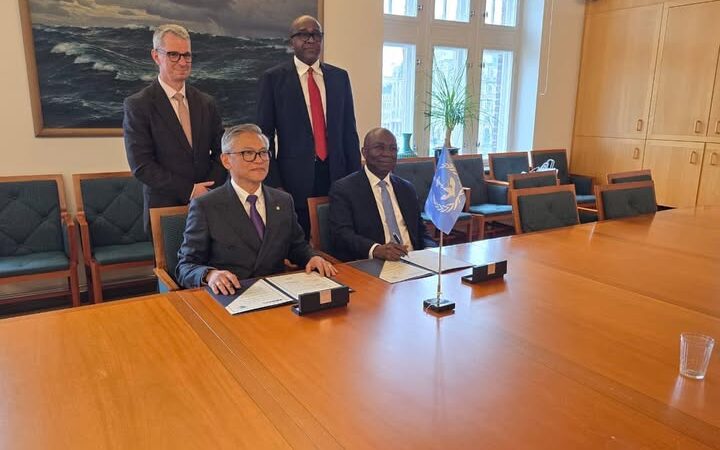

https://en.wikipedia.org/wiki/Keith_Tantlinger

http://mediarail.be/Fret/Intermodal/Conteneur%20maritime/Conteneur_01.htm