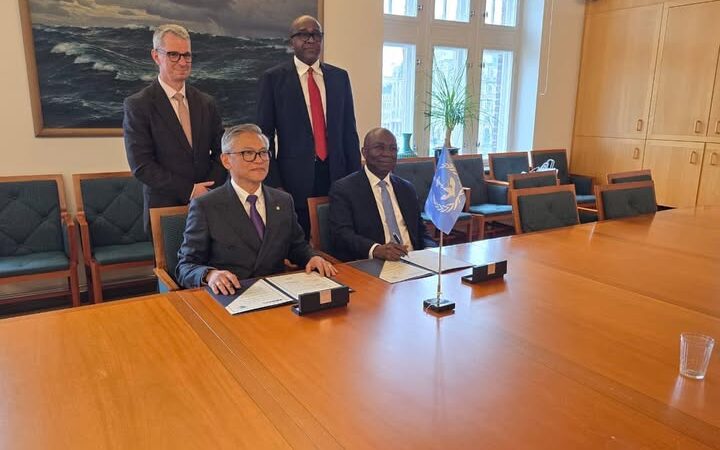

Shell and Hapag-Lloyd collaborate on marine fuel decarbonisation and sign multi-year LNG supply agreement

Shell Western LNG B.V (Shell) and Hapag-Lloyd today announced the signing of a multi-year agreement for the supply of liquefied natural gas (LNG) to Hapag-Lloyd’s ultra large dual-fuel container vessels of 23,500+ twenty-foot equivalent units (TEU). Bunkering for these twelve new vessels is expected to commence during the second half of 2023 and LNG will be supplied in the Port of Rotterdam. The modern ships will be deployed on Europe-Far East routes and call at major ports including Rotterdam, Hamburg, Singapore, and Shanghai.

Using LNG enables Hapag-Lloyd to immediately reduce the CO2 intensity of these vessels by up to 23% compared to conventional fuels¹. Additionally, the use of LNG supports the almost complete reduction of particle emissions². This is another important step for Hapag-Lloyd to reduce emissions and decarbonise its fleet in line with its goal of becoming net zero carbon by 2045.

As a hard-to-abate sector, Shell is exploring the viability of, and investing in a range of fuels, technologies and solutions that will help decarbonise shipping. This includes the use of LNG, where through an extensive network of 15 LNG bunkering locations in 10 countries globally, Shell has already achieved over 1,000 safe ship-to-ship bunkering operations to its marine customers.

In addition to the LNG supply agreement, Shell and Hapag-Lloyd have entered into a strategic collaboration agreement intended to accelerate the further decarbonisation of alternative marine fuels. Initial focus will be given to developing the potential of additional low carbon fuels solutions including liquefied biomethane and the hydrogen-based fuel liquefied e-methane. Liquefied biomethane as a marine fuel has the potential to reduce greenhouse gas emissions by between 65% and 100%³.

Tahir Faruqui, General Manager, Head of Downstream LNG at Shell, said: “We are delighted to have partnered with Hapag-Lloyd on this important initiative. Shipping decarbonisation must accelerate and, as the lowest-carbon fuel available at scale today, LNG is a key part of the transition to lower-carbon marine fuels. As we look to the future, we are committed to working with leading shipping companies like Hapag-Lloyd to establish the credible pathways to net zero.”

Jan Christensen, Senior Director Global Fuel Purchasing at Hapag-Lloyd: “We are pleased to share the execution of this long-term supply agreement. Hapag-Lloyd has finalised a contract with Shell which secures flexible LNG supply at competitive terms. Furthermore, we are excited about our agreement with Shell to explore further decarbonisation opportunities as it allows both businesses to drive impactful change in the industry. Collaborations like this are crucial in helping us deliver our sustainability strategy while also improving emissions in maritime shipping. Ultimately, this enables our customers to decrease their carbon footprint as well.”

This announcement supports Shell and Hapag-Lloyd’s long-standing collaboration, which over the past years included the LNG bunkering of the “Brussels Express”, the world’s first large container ship that was converted to gas propulsion.

1 2nd Life Cycle GHG Emission Study on the Use of LNG as Marine Fuel” study by Sphera for SEA-LNG and SGMF (2021) The benefit is highly dependent on the engine technology installed with the 23% savings referring to a high pressure, 2-stroke slow speed diesel dual-fuel engine compared to Very Low Sulphur Fuel Oil (VLSFO).

2 2nd Life Cycle GHG Emission Study on the Use of LNG as Marine Fuel study by Sphera for SEA-LNG and SGMF (2021). Local combustion pollutants, specifically sulphur oxides (SOX), nitrogen oxides (NOX) and particulate matter (PM), are reduced when using LNG compared with conventional marine fuel oils (including HFO, VLSFO, MGO). Due to the negligible amount of sulphur in the LNG fuel, SOX emissions are reduced to near zero as long as the dual fuel engines are running mainly on LNG. NOX and particle matter is reduced by up to 95 to 96% for the case of using an otto-cycle combustion engine.

3 The liquefied biomethane (LBM) potential greenhouse reduction is applicable for a 100% blend of LBM. The 65% emission reduction limit is set by the Renewable Energy Directive II for transportation of biofuels – summarised in an ICCT Policy update. The actual emission reduction depends on the feedstock, process, with the correct certification in place. The carbon intensity of the LBM can vary, as it comes from a variety of feedstocks (REDII compliant and officially accredited.) The LBM carbon intensity can vary from -97 gCO2e/MJ (from REDII default values for wet manure closed digestate, using 6.7gCO2e/MJ for liquefaction) to 32.9gCO2e/MJ (the REDII threshold which requires 65% CO2e savings compared to the fossil fuel comparator value of 94 gCO2e/MJ). This is also highlighted in the Smart Freight Centre Bio-LNG (LBM) White Paper 100% CO2e emissions reduction can be reached by optimising liquefied biomethane from different feedstocks and processes with varying carbon intensities. Shell liquefied biomethane comes from waste and residue, non-food and feed feedstocks following the EU’s guidelines (REDII). CO2e (CO2 equivalent) refers to CO2, CH4, N2O.

Source : Hapag-Lloyd