SIMULATION AS PROBLEM SOLVING APPROACH

STS CRANE TYPE & MODE OF OPERATIONS SELECTION

Simulation as a Methodology for Decision Making

Simulation as a Methodology for Decision Making

The majority of decisions in port development projects are made on the basis of Historical Data, Assumptions of future economic trends as well as on the technological development (performance capabilities) of Port handling equipment.

While it is known that historical data and past trends are a good starting point, by themselves they cannot validate a sound business decision making without augmenting the Historic Data with a thorough Simulation of the variable attributes as well as a close look into the technical capabilities of your handling asset.

To make a sound business decision about your future Ship to Shore (STS) Crane requirements and specifications which will have a long term financial and performance impact, you will require more than the traditional Static operational modelling.

To make a sound business decision about your future Ship to Shore (STS) Crane requirements and specifications which will have a long term financial and performance impact, you will require more than the traditional Static operational modelling.

Why simulation?

While the Operational Modelling allows the designer to understand the static average performances and general requirements, it does lack the analytical power to expose your business vulnerability to some particular risks & attributes. This is where the Simulation power is put into the service of the designer, as it allows to understand the effect of each, or a group of attributes on the performance outcome and enable the prediction of the behaviour of a production system when variation occur. (the what if scenarios analysis).

This is the optimal approach for complex problems which do not have an easy analytical solution.

This is the optimal approach for complex problems which do not have an easy analytical solution.

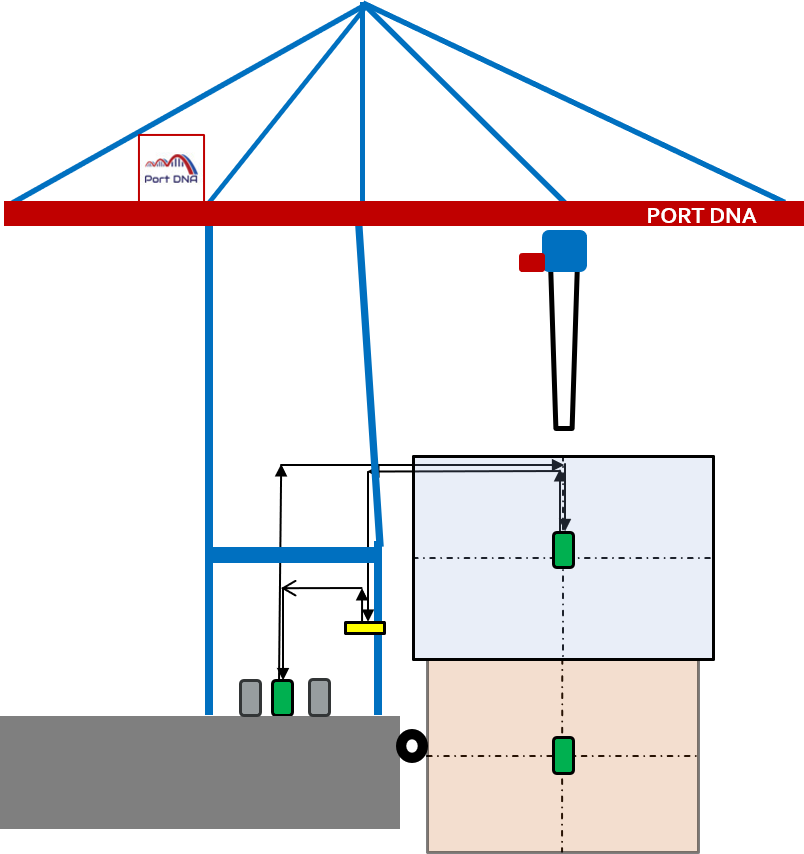

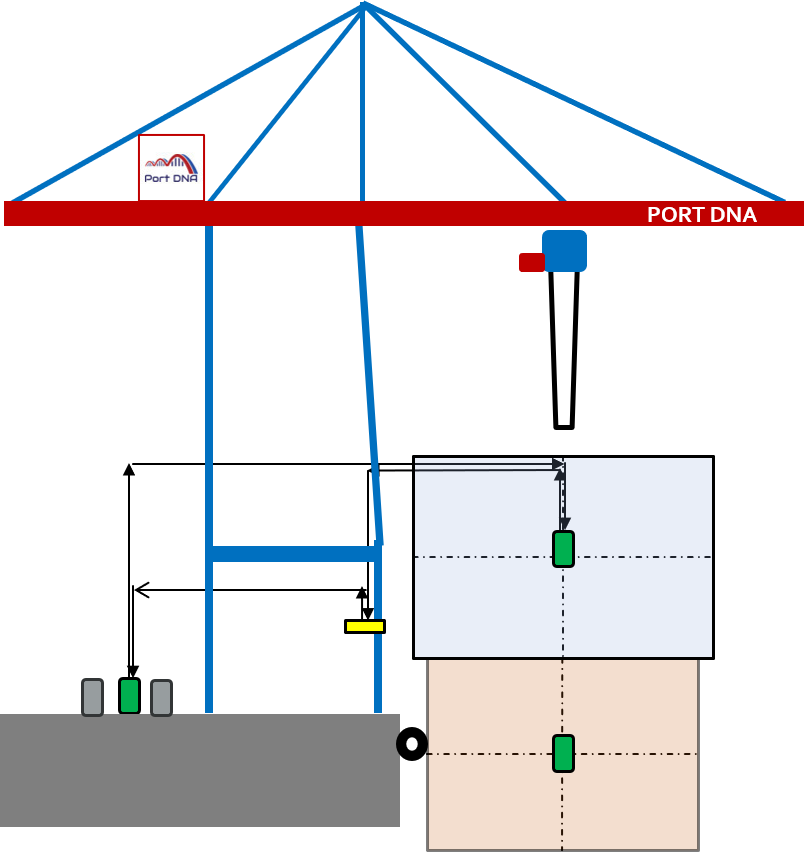

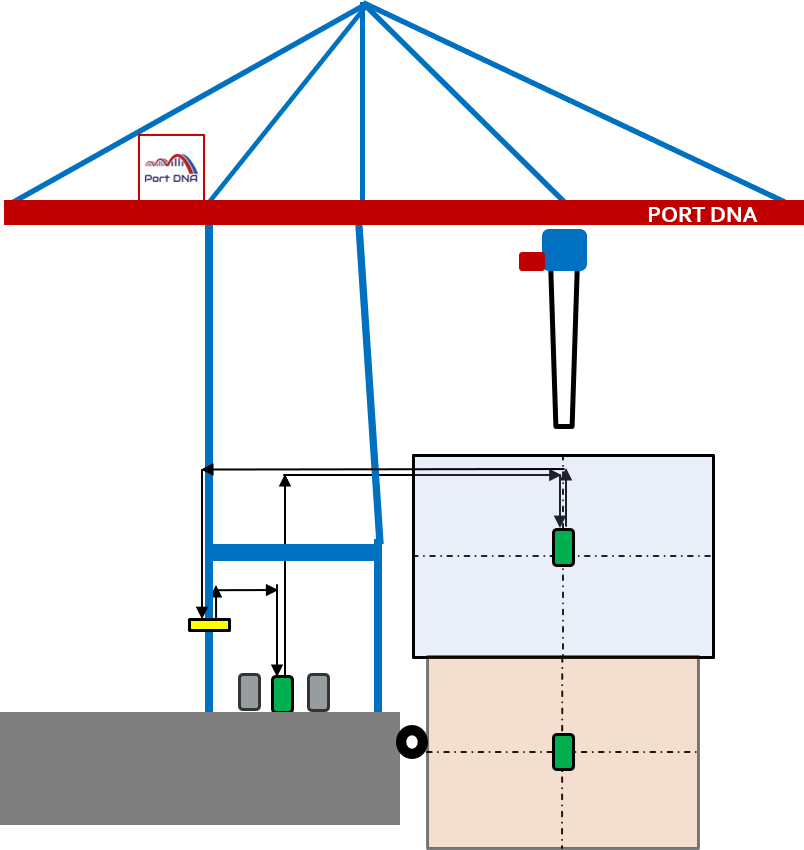

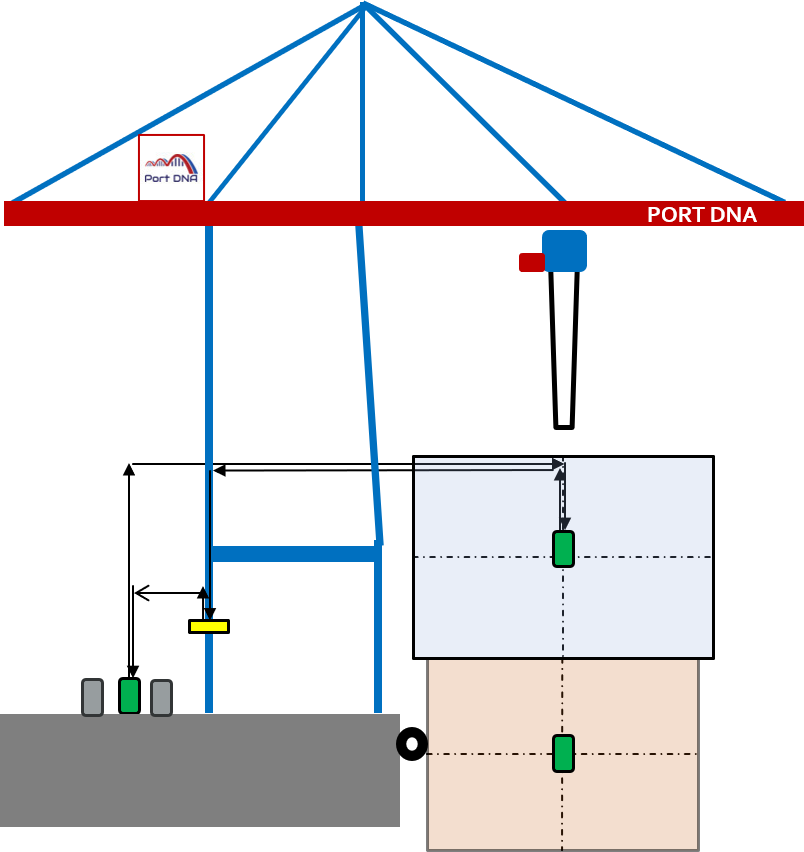

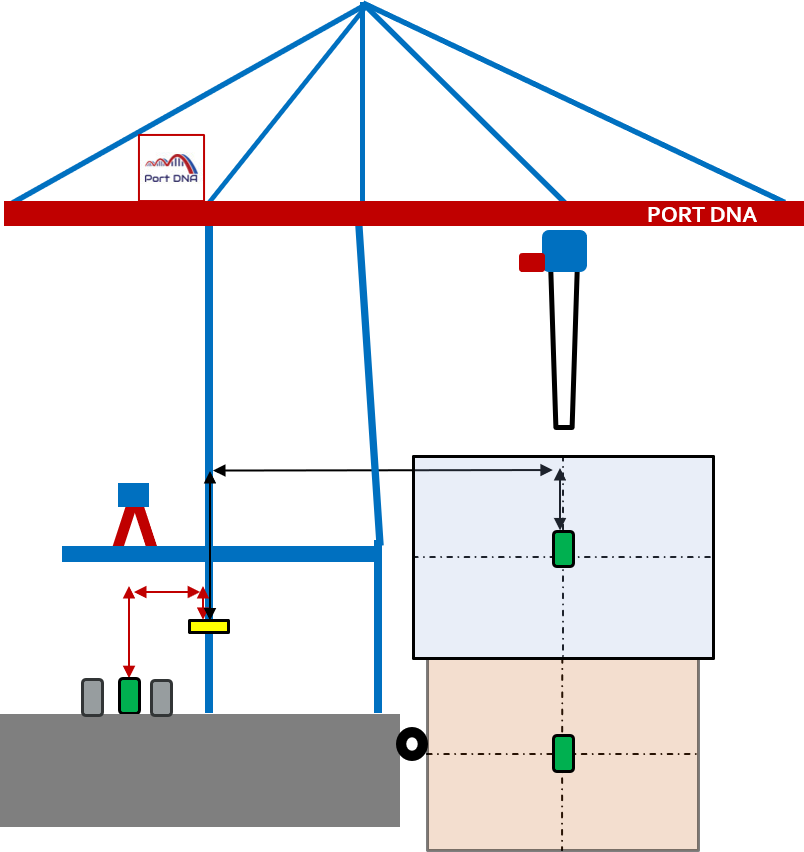

In practice and thanks to the virtual environment of simulation, the Port Designer is able to test different configurations and specifications for an STS crane and identify the different performance capabilities that each configuration offer, without the burden of the time constraint, resources, cost and real-life risks to people and assets…

Simulation allows to simultaneously combine a large number of variations or a single variation and explore hundreds of thousands of scenarios in a relatively short time. Among the variable attributes that can affect an STS crane productivity performance are: Hoist speed, Trolley speed, Vessel Draft (Height of tiers above deck and below deck), Twist lock platform position (Waterside or Landside), In-Gauge or Back reach Operations, Twist lock platform Height, Landside Rail offset from the cope line, operators skills and so on …

Simulation Outcome!

Simulation Outcome!

What I like most about simulation is that it delivers a data range as output instead of a single data point; Identifying a full range of benefits provide a meaningfully comprehensive analysis to the port designer and to the senior management than a single Data Point.

Next to the range of Productivity performance, the simulation enables the designer to identify and quantify the attributes that are likely to positively or negatively contribute to the Crane performance which allows management to focus their efforts on the problematic attributes. (Determine the cause/effect analysis)

There are many ways in which you can present the numerical outcome of Modelling, depending on what you want to achieve:

There are many ways in which you can present the numerical outcome of Modelling, depending on what you want to achieve:

a) Rounded number: ~30 MPH – Clear & easy to communicate. Downside is it can look like it is made up and wont account for variations.

b) Decimal Number: 30.48 MPH – The number seems to be calculated, so less likely to be challenged, however is still shows an average and does not account for the variations in the production system.

c) Data Range: {29.34 – 31.2 MPH} – Obviously the number is calculated with the worst- and Best-case scenarios as well as the most likely scenario, also it’s hard to be wrong when the range is followed with a certainty level.

Simulation modelling Benefits

Simulation modelling Benefits

I enjoy the use of Simulation, as it minimises the need for real life tests and spare thousands of manhours & dollars for organizations. Furthermore, it allows the Port Designer to run simultaneously a large number of attributes variations calculations in very short time and ensure all the possible scenarios have been considered.

Simulation modelling can be used for a number of different reasons

a) Developing scientific approach to decision making instead of gut feeling or emotion

b) Test the effect of changes in one or multiple attributes in the outcome

c) Support and increase senior management confidence in the decision making

Closing Note

When using Simulation (Similar to when making mathematical calculation) the assumptions data quality & validity is crucial, otherwise it will be Garbage In => Garbage Out.

Written by Lyes CHEBREK, PORT DNA _Feb 2021